What you need to know about Critical Flashings

What you need to know about Critical Flashings

Flashings play a key role in the performance of any building exterior building envelope. Together with a cladding system installed over a drained and ventilated cavity system, flashings form the primary line of defence deflecting liquid water to the exterior of the building or assisting it to drain out in planned locations. Essentially flashings are the most critical part of any cladding system and are widely overlooked and under detailed in the industry today.

Identifying and Managing Risk

It’s a well-known fact that even in a ‘leaky building’ the main face of the cladding systems more often than not perform just fine. It’s the flashings at the joints, junctions and penetrations that leak when not properly considered or constructed. We refer to these areas as ‘critical junctions’ and work to eliminate them in new home design. We then work to make them ‘robust’ and ‘bulletproof’ when undertaking remedial design to an existing building.

These are the areas that most architects and designers shy away from because solutions get into a level of detail and building science they simply don’t understand or have time for. Unfortunately, these are the exact areas that contractors need the most assistance with so should be a priority for every project. Each critical junction resolved in the planning stage creates substantial efficiencies on site and eliminates the potential of failure down the track.

Resolution Requires Custom Solutions

The resolution of these high risk elements often requires an ‘out of the box’ or ‘custom’ solution which eliminates or manages water ingress. The New Zealand Building Code’s acceptable solutions for some unknown reason allows the use of cut, folded, riveted and sealed powder coated light gauge steel! These solutions are cheap, ineffective and ultimately will not perform in the long term.

The most effective and robust solutions involve custom fabricated, thick gauge stainless steel or aluminium flashings that are rigorously designed, assessed, and fabricated to suit each individual junction. Many variables are considered during the staged 3D design of these flashings and a comprehensive level of thinking is required to manage the effects of liquid water and wind speed/pressure. The kicker is, that when done right, these custom robust solutions don’t cost that much more cost than the cheap and ineffective light gauge steel “solutions”.

Custom Flashings

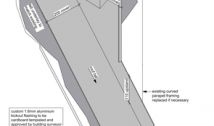

These custom flashings are designed in house, measured and have cardboard templates built on site before being approved for custom fabrication from 2mm or 3mm thick stainless steel or aluminium (depending on location). These are then checked for fit on site before being taken away for powdercoating (aluminium) or sometimes electro polishing (exposed stainless steel). Finally these are then returned to site for installation.

This process is quite involved however these are the critical junctions that fail and it will literally cost 10+ times the amount to upgrade them later so spend your money wisely and in the right places. Critical junctions require bulletproof and long term weather-tight solutions . It is this effort to go over and above standard industry practice and NZ Building Code Acceptable Solutions that will protect you in the long term.